Trade Tacts International Pvt. Ltd., provides its customers with complete compressed air systems; their service, maintenance and product distribution through its international partners.

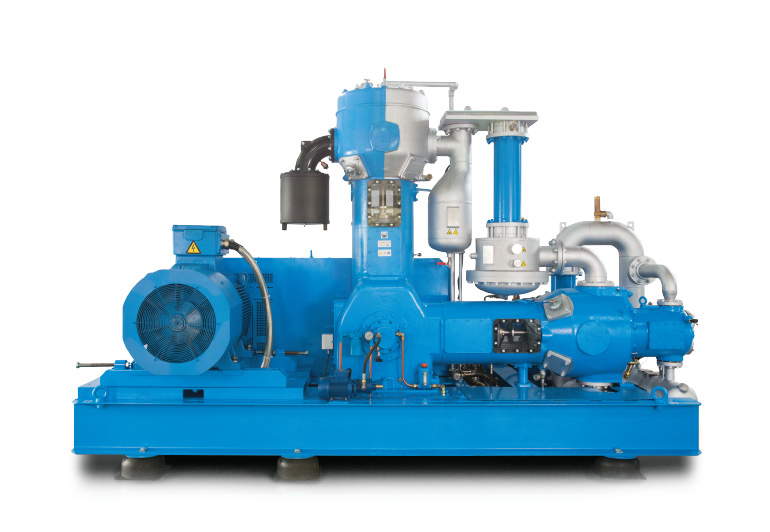

AF Compressors, Ateliers François S.A. is a family-owned company which roots are back to 1870 in Liège, Belgium. AF compressors has developed and produced reciprocating piston compressors for various industrial applications during the years. Today, and since the early 2000’s AF is the market leader for 3-stage oil free compressors for the PET bottling applications. With more than 6500 units in 180 different countries and yearly sales figure ca. 100Mo€, the portfolio also includes 15 daughter companies and 20 official agencies around the globe. Most recently, AF has launched its two-stage oil free compressors including all technical improvements. The new range is a groundbreaking innovation for 7 bar and 10 bar, low pressure oil free compressors capacities ranging from 7,2 m³/min up 58 m³/min and for the 20-40 bar oil free PET compressors capacities from 150 up to 3300 m³/h applications. AF Compressors systems are designed for low energy, carbon footprint reduction and sustainable growth. AF compressors are sustainable for decades.

RENNER is a specialist in the manufacture of screw compressors - lubricated and non-lubricated. Screw compressors generate compressed air by means of rotating intermeshing spiral rotors. These compressors are often also called screw air ends. Screw compressors are particularly suitable when continuous, consistent pressure is required. These machines are real endurance runners. Screw compressors are often found in industry and trade.

In contrast to piston compressors, screw compressors are still relatively new on the market. Although the principle was developed as early as the 19th century by the German, Heinrich Krigar, the screw compressor did not really gain acceptance until after the Second World War.

Screw compressors are characterized by their relatively small design and low mass. They run quietly and supply compressed air with a very uniform flow. Compared to piston compressors, screw compressors are significantly quieter. This is because there are no high mechanical forces that have to be slowed down or accelerated. The effect: a lower resonance oscillation and therefore less sound.

Parker is the global leader in motion and control technologies, providing precision-engineered solutions for a wide variety of mobile and Industries. Parker can be found on and around everything that moves. At Parker we have an unmatched breadth and depth of products that originate from a global leadership position in nine core Motion and Control technologies that include Compressed Air Gas Purification & Filtration, Electromechanical, fluid and gas handling, CO2 Filtration, hydraulics, pneumatics, process control, sealing and shielding. We can apply these products and technologies individually to solve customer challenges that are simpler, or we can combine them to develop systems that address challenges that are complex.

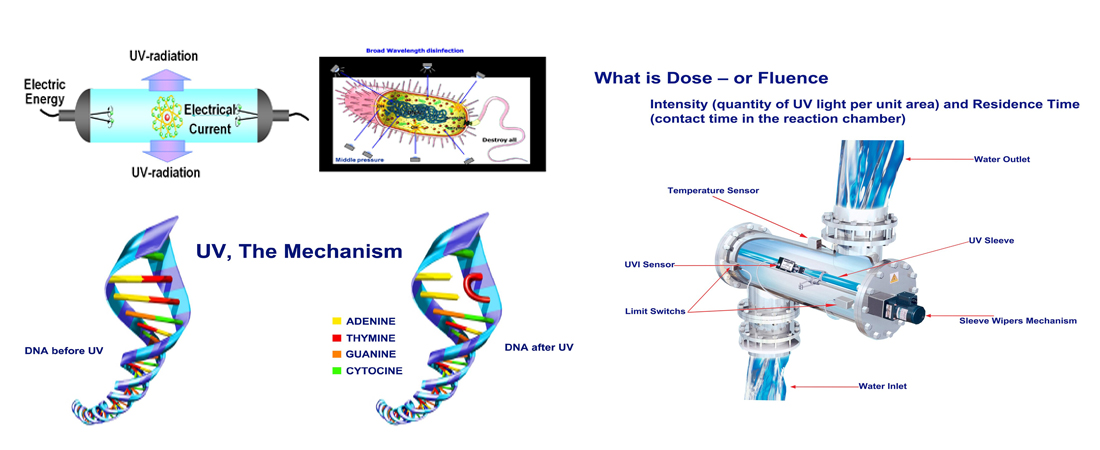

NUVONIC is the world leader in the development of disinfection by ultraviolet light technology for the last 85 years. UV energy not only disinfects and sterilizes but also deozonises, dechlorinates, and reduces total organic carbon (TOC). Disinfection and sterilization can be done for liquid, surface, air, and odor removal. Systems from NUVONIC are used in municipal water treatment for million gallons per day, at individual food, beverage, and pharmaceutical plants, swimming pools, fishponds, air conditioning systems, odor control and surface treatment of foods, etc.